Theme Color Chooser

Choose a test user to login and take a site tour.

-

New Facebook Clone Theme darkgreen

New Facebook Clone Theme darkgreen -

New Facebook Clone Theme darkorange

New Facebook Clone Theme darkorange -

New Facebook Clone Theme darkpink

New Facebook Clone Theme darkpink -

New Facebook Clone Theme darkred

New Facebook Clone Theme darkred -

New Facebook Clone Theme darkskyblue

New Facebook Clone Theme darkskyblue -

New Facebook Clone Theme darkyellow

New Facebook Clone Theme darkyellow -

New Facebook Clone Theme default

New Facebook Clone Theme default -

New Facebook Clone Theme green

New Facebook Clone Theme green -

New Facebook Clone Theme orange

New Facebook Clone Theme orange -

New Facebook Clone Theme pink

New Facebook Clone Theme pink -

New Facebook Clone Theme red

New Facebook Clone Theme red -

New Facebook Clone Theme yellow

New Facebook Clone Theme yellow

Personal Information

- First Name: Xi

- Last Name: Ray

Personal Details

- Gender: Male

- What's New

- Friends

- Info

- Compliments

-

More +

- Videos

- Channels

- User Reviews

- Events

What's New

-

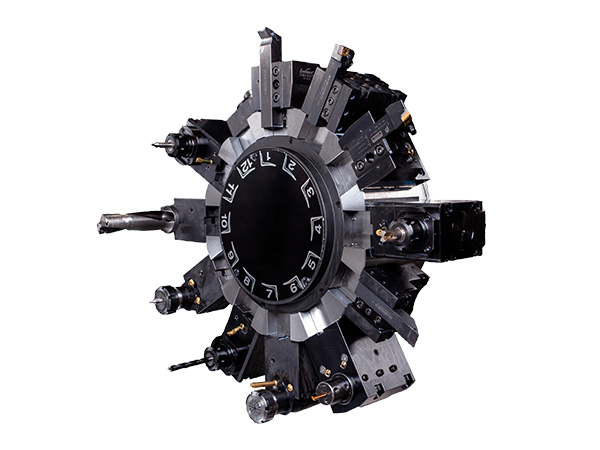

The PSC Tool Holder Series by Jiaxing XiRay Industrial Technology Co., Ltd. provides cutting-edge solutions for manufacturers looking to achieve superior precision and efficiency in their machining processes. Designed to meet the rigorous demands of high-performance machining, the PSC series leverages advanced technology to enhance rigidity, stability, and accuracy, making it ideal for industries such as aerospace, automotive, and medical devices. Whether you're working with milling, turning, or multi-axis operations, XiRay’s PSC Tool Holders deliver optimal performance in any environment. The PSC Tool Holder Series is based on the Polygon Shank Conical (PSC) interface, designed according... more

- Translate

-

In the rapidly evolving world of manufacturing, precision, efficiency, and reliability are the pillars upon which cutting tools are built. Cutting tools are essential components that allow manufacturers to achieve these goals, whether working with metals, plastics, or composite materials. As industries push toward higher performance and faster production cycles, the need for innovative cutting tools continues to grow. Our expansive offering of over 150,000 types of cutting tools provides diverse solutions tailored to meet the unique demands of modern machining.

Our cutting tool systems are designed to support a wide array of machining processes, ensuring optimal performance across various... more - Xi Ray has updated a new cover photo.

- Xi Ray has added a new profile photo.

There are no more results to show.